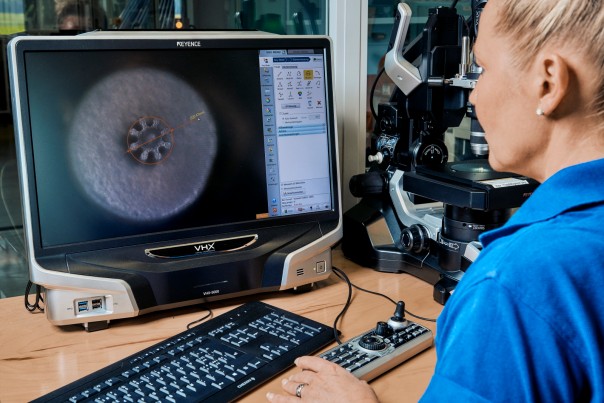

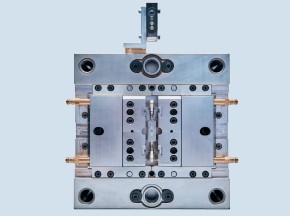

All steps in the process are monitored, recorded, analyzed and evaluated in detail using the latest testing and measuring techniques. Reliable documentation and its archiving are part of our routine services.

Our quality assurance department is staffed exclusively by specialists who are trained in the demanding measurement of high-precision plastic parts.