Quality is produced

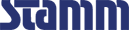

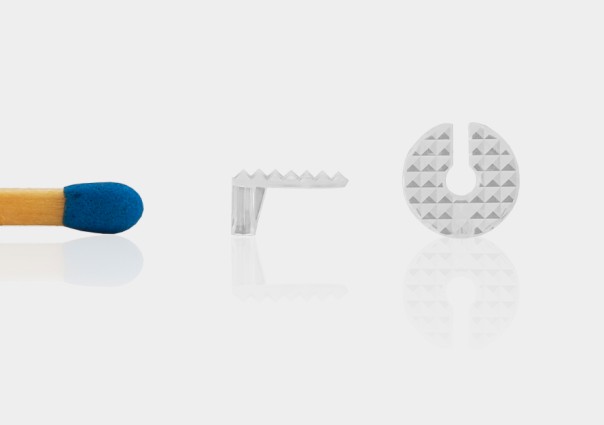

We have been active in the field of precision injection molding for over three decades.

Through the combination of modern machinery and the experience of our skilled workers, we are able to produce precision components in millions of pieces.

We also fulfill tolerance requirements of ± 0.01mm. The part weights are between 0.01g and 150g