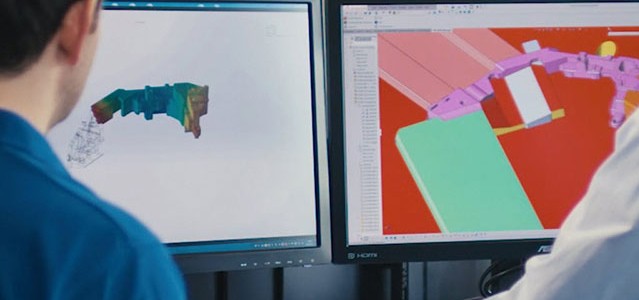

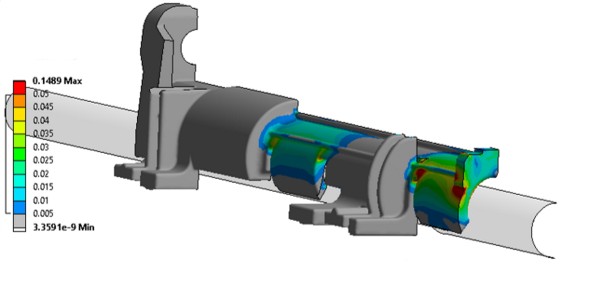

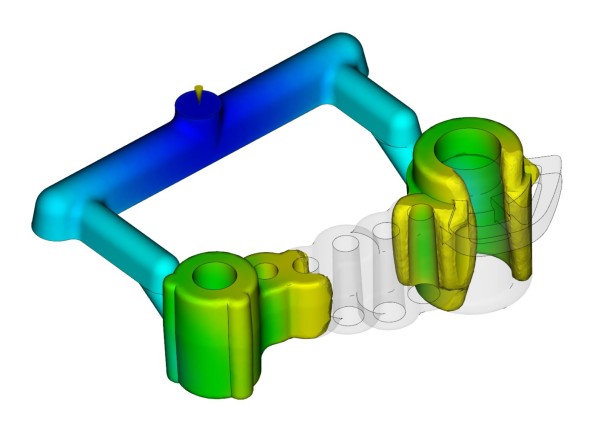

Compared to the overall costs of the customer product, the direct costs of the SFS products embedded therein often make up less than 1%. The associated efforts on the customer side, such as procurement or logistics, are many times more. That's why it is our goal to optimise the overall costs of our customers.

The advantage: customised products and intelligent solutions not only create sustainable added value for the customer, they also consolidate the partnership and lead to a stronger differentiation. This goal requires a corresponding attitude: the constant desire to invent success together.